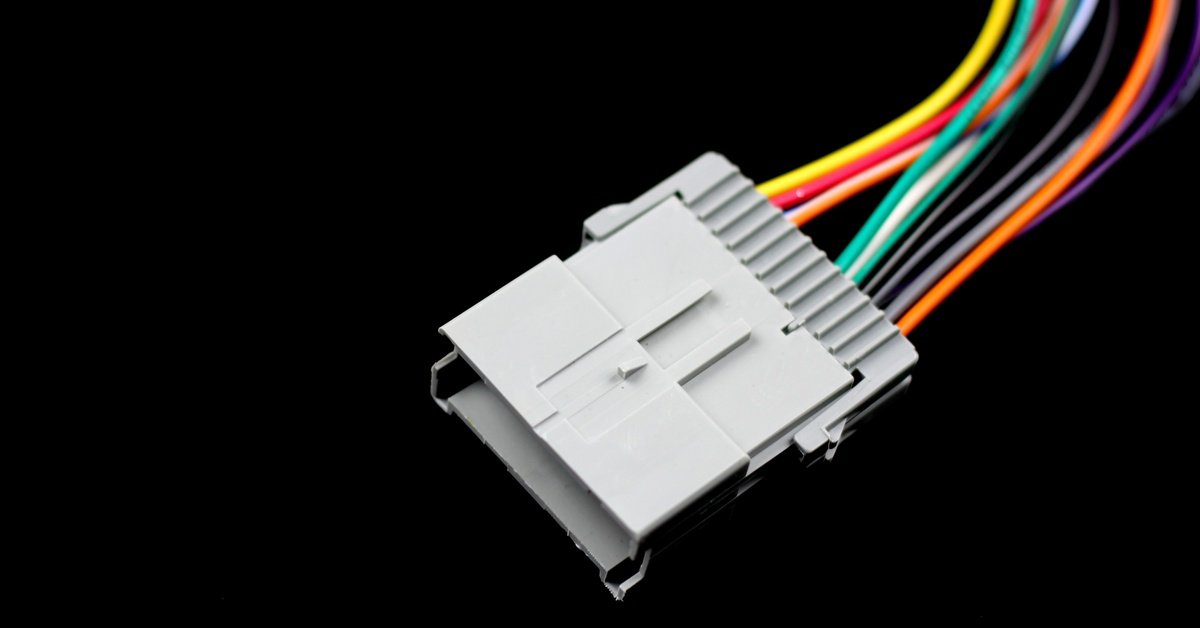

Electrical connectors play a crucial role in keeping your systems running smoothly, but they don’t last forever. Like any component that handles power and data transmission, connectors deteriorate over time and require regular attention. Recognizing the warning signs early can save you from costly downtime, equipment damage, and safety hazards. Here are five telltale indicators that your electrical connectors need immediate maintenance.

Visible Corrosion

Corrosion ranks as the most obvious sign that your connectors need attention. You’ll spot this problem as green, white, or brown discoloration around the metal contact points. Moisture, salt, and chemical exposure accelerate corrosion, creating a barrier that prevents proper electrical flow.

Industrial environments with high humidity or exposure to corrosive substances see this problem more frequently. When corrosion spreads across multiple connection points, the 6-cavity plugs could have poor contact, leading to intermittent failures that become increasingly difficult to diagnose.

Overheating

Temperature spikes in electrical connectors signal serious trouble ahead. You might notice discolored plastic housing, melted insulation, or a burning smell near connection points. Overheating typically results from increased resistance caused by loose connections, corrosion, or worn contact surfaces.

Promptly addressing these warning signs prevents costly repairs and hazardous situations. Touch testing can help identify hot spots, but use caution and appropriate safety equipment.

Loose Connections

Physical movement or vibration in your connectors indicates worn or damaged locking mechanisms. Connectors should fit snugly together without any wiggle room. Loose connections create intermittent electrical contact, leading to voltage drops, signal interference, and potential arcing.

Manufacturing equipment, vehicles, and outdoor installations commonly experience this issue due to constant vibration and thermal cycling. Check connection tightness regularly, especially in high-vibration environments where mechanical stress takes a heavy toll.

Damaged Insulation

Cracked, brittle, or missing insulation exposes your electrical system to multiple risks. Environmental factors like UV radiation, extreme temperatures, and chemical exposure break down insulation materials over time. Damaged insulation allows moisture infiltration, creates short circuit risks, and exposes personnel to electrical hazards.

Look for visible cracks, color fading, or areas where the insulation feels hard and inflexible. Flexible cables and connectors in moving applications tend to suffer insulation damage more quickly than those in stationary installations.

Frequent Electrical Failures

Recurring electrical problems often stem from connector issues. These failures might appear as intermittent equipment shutdowns, unexplained error codes, or inconsistent system performance. While other components could cause these symptoms, worn connectors frequently contribute to system instability.

Keep detailed records of electrical failures—patterns often emerge that point directly to specific connector assemblies. Multiple failures in related circuits strongly suggest that connector maintenance needs immediate attention.

Regular connector maintenance prevents expensive repairs and dangerous situations. Address these warning electrical connector signs promptly rather than waiting for complete failure. Professional electrical maintenance services can thoroughly inspect your systems and recommend appropriate repair or replacement strategies based on your specific operating conditions.